Since 1998

Our expertise

Specialist in sheet metal processing, we work custom metal for our customers in France

and at international: laser cutting, stamping, bending, assembly.

Die tooling

ATPA has expertise in stamping which allows us to manufacture your most complex parts.

Our design office is equipped with 3D CAD software used to design die tooling needed to produce your stamped parts.

We can offer you classic tools in steel (longevity) or in TL-1000 resin (economical) to best adapt to the constraints of your project.

We are able to use your plans and models of 3D parts in DXF, DWG, IGS, STEP formats.

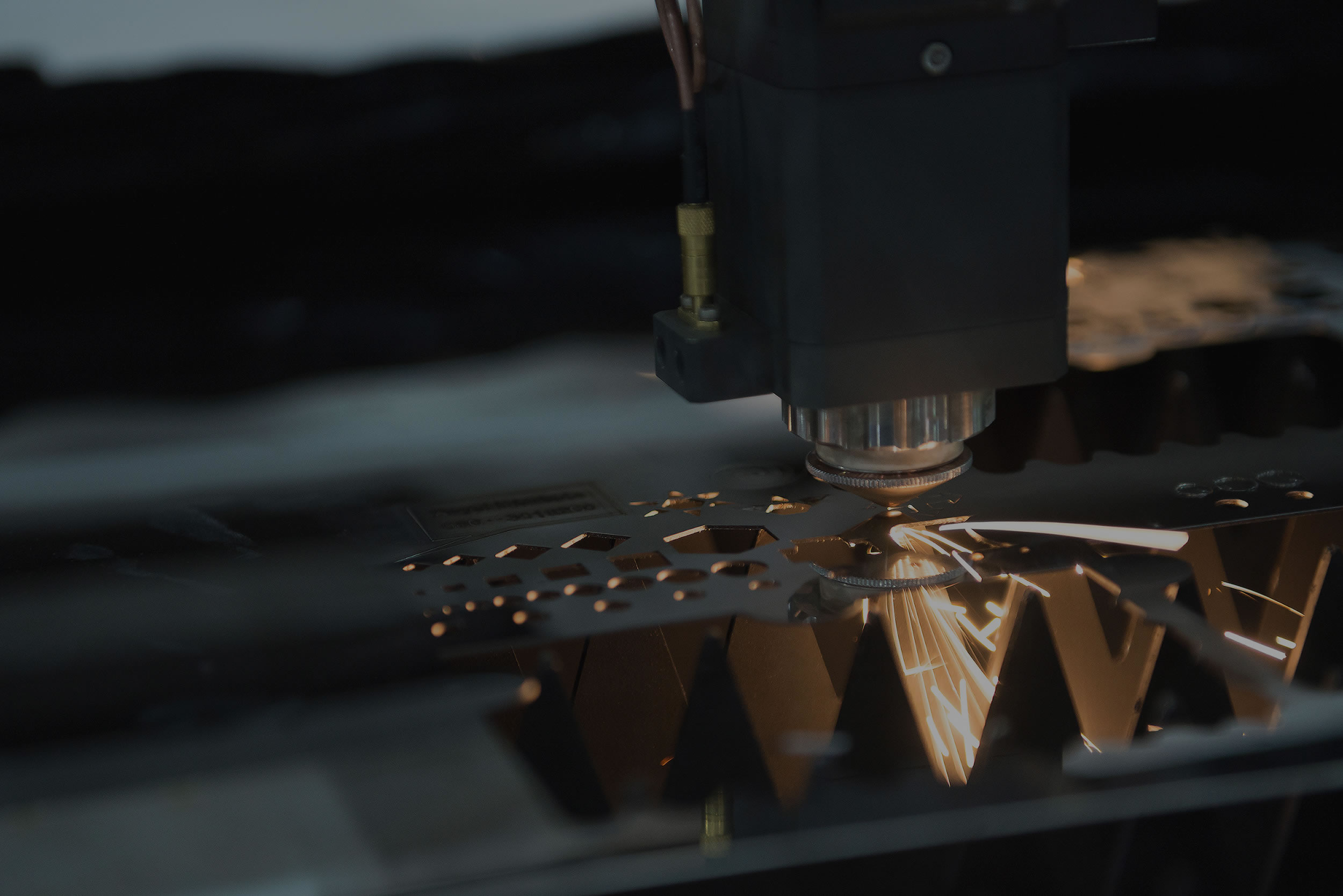

2D, 3D and pipes laser cutting

This technology allows complex shapes cutting on sheet and formed parts (stamped, profiles, pipes) with high precision for all your industrial and decorative projects.

We have two laser cutting machines capable of cutting your parts in all types of metals (raw and coated steel, aluminium, stainless steel, brass) for thicknesses between 0.5 mm and 16 mm

We are able to use your plans and models of 3D parts in DXF, DWG, IGS, STEP formats.

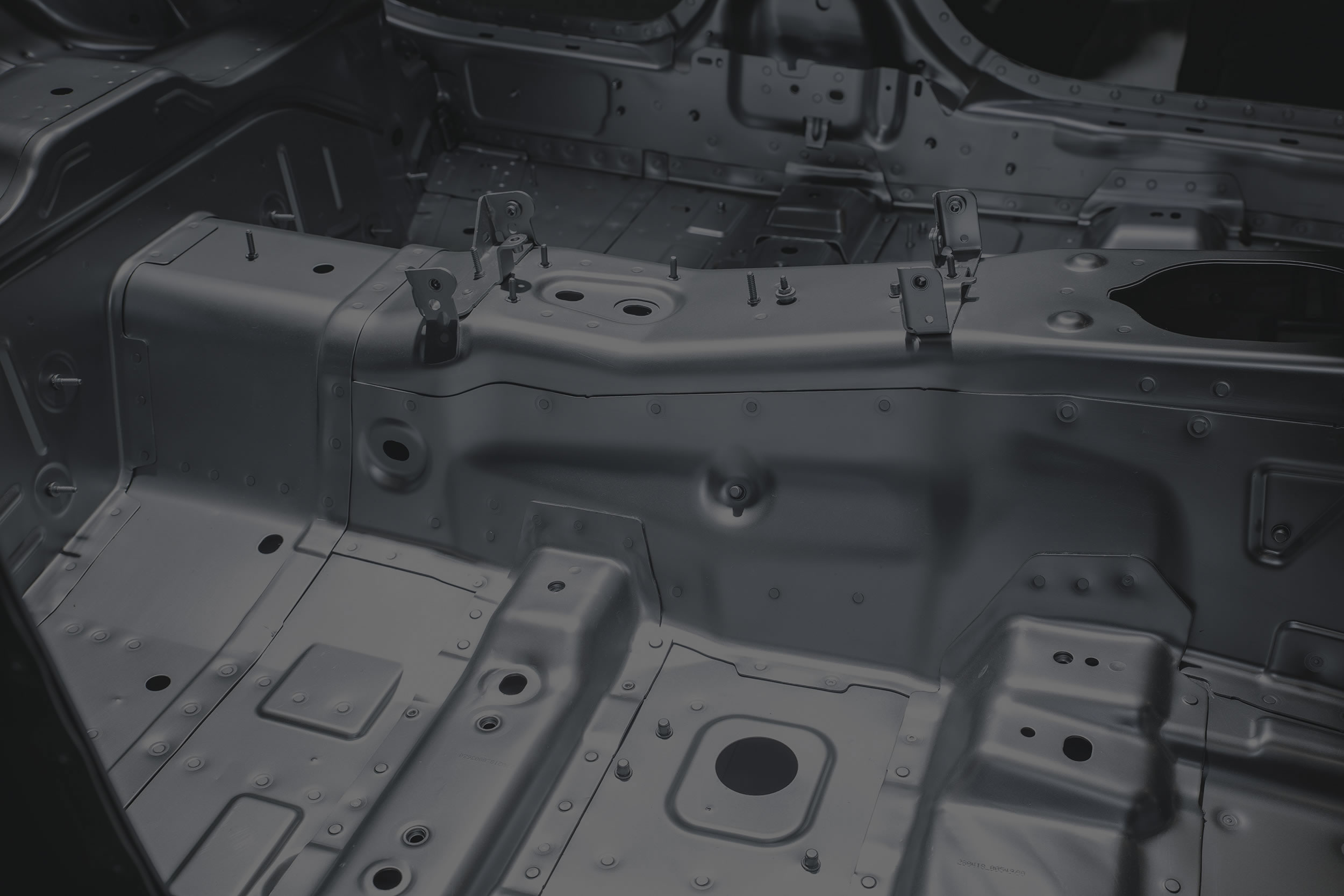

Cold Stamping

This manufacturing process allows the production of parts with complex shapes that cannot be developed.

From the tools developed by our design office, we can produce your most demanding parts

Our machines allow the manufacture of stamped parts up to 3 ft in circumference.

Hot stamping

In the case of very complex parts not achievable in conventional stamping, we have a heating furnace to work the parts hot and ensure their production by guaranteeing mechanical properties in accordance with your requirements.

From the tools developed by our design office, we can produce your most demanding parts

Our machines allow the manufacture of stamped parts up to 3 ft in circumference.

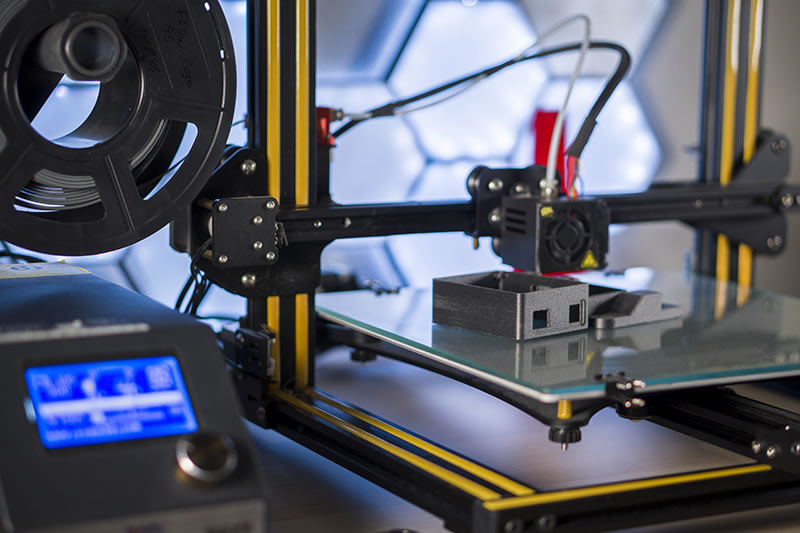

3D Printing by fused deposition (FDM)

Having become essential in recent years, the use of 3D printed parts is now present in all applications area, quick to manufacture and economical, they are a real asset for your projects.

Our expertise in this field allows us to offer you PLA parts for all kinds of applications: appearance parts, test parts, volume parts, etc.

Our machines allow us to print parts included in a 17.7 x 17.7 x 18.5 in. format

We are able to use your plans and models of 3D parts in STL, IGS, STEP formats.

Bending / Folding

This economical manufacturing process makes it possible to produce bent parts up to 8.2 ft in length.

We have several CNC bending machines that offer a high level of precision and allow complex bending sequences.

Assembly

We manufacture all types of mechanical assembly. The various assembly processes available allow to conform at the requirements of all your projects.

We offer the assembly of your parts by welding (cords or points), brazing or riveting.

Mounting of accessories

For all your parts we can install accessories to offer you many possibilities of integration.

We are able to equip your parts by welding or crimping with studs, screws, nuts and thread inserts.

Surface treatment

The finishes offered for your parts make it possible to provide them resistance and an appearance that meets your requirements.

To fight against phenomena of corrosion, oxidation or to give a decorative aspect, we are able to deliver your parts with a black cataphoresis treatment, zinc plating or the paint of your choice.

Other specific treatments can be performed on request.

Metrological Control

This step is used for controlling the manufactured parts and to validate their conformity.

We are equipped with a three-dimensional digital control bench that allows us to guarantee the level of precision expected for your parts.

All our parts are checked during manufacture, and we are able to deliver them accompanied by a detailed inspection report.